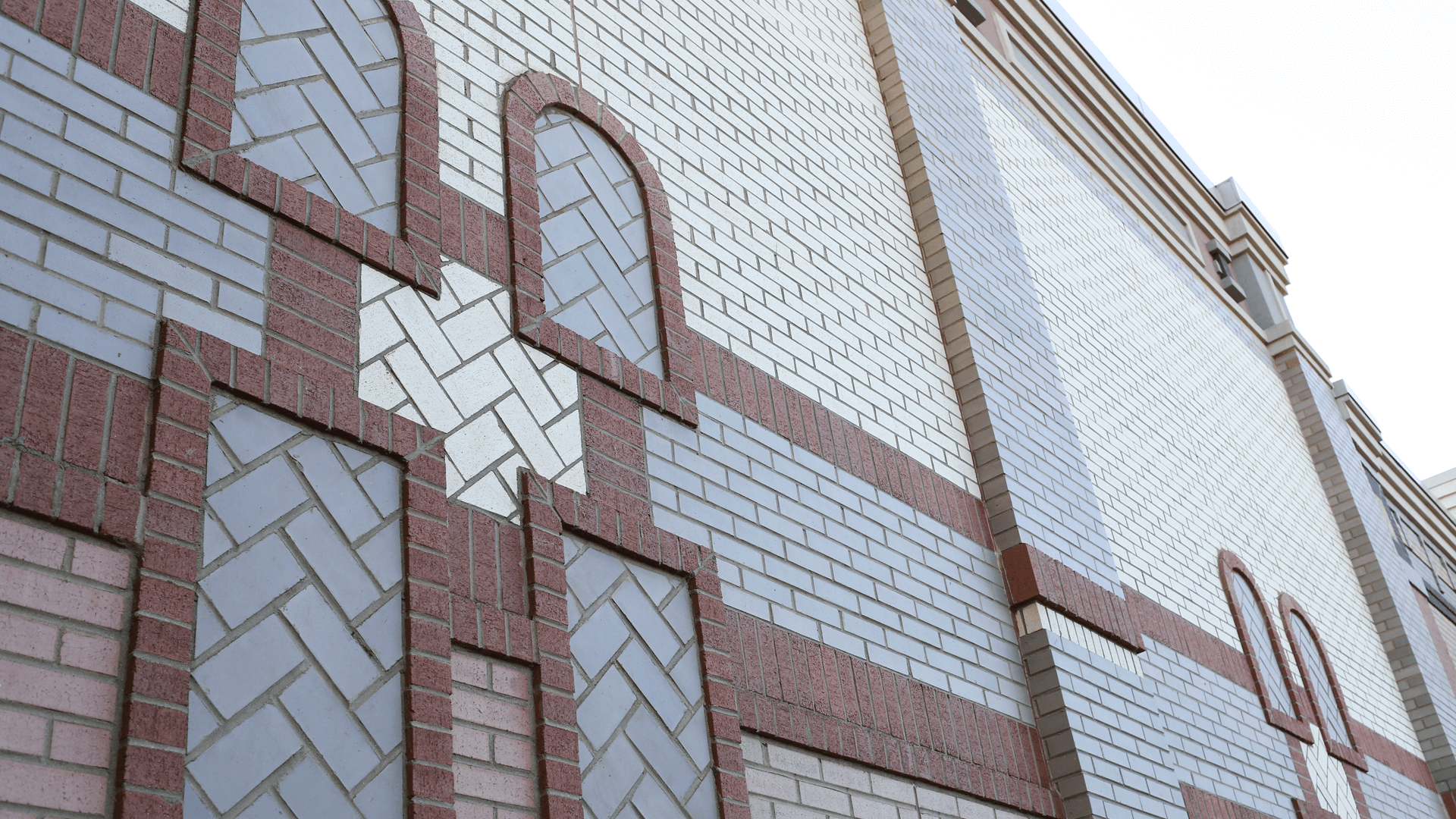

Brick can be manufactured in many ways to give unique appearances. The different processes may be characterized as red bodied with textured or sand faces, ad-mix or thru-body, wood moulded or hand-made, and thin brick. Brick are made from clay, shale, sand, water and other additives. The process of manufacturing involves mining the clay/shale, grinding, pressing into a green form, adding coloring, drying, firing to 2000+ degrees Fahrenheit, and then packaging. Most brick deliveries are by truck, thought some go by rail for longer distances.

Red-bodied or Sand-faced

The most basic brick process is to dig clay from the earth and process it into a form. Then a brick manufacturer can add a coating of sand to the body and fire the unit to suitable specifications. These brick can also have several textures such as wirecut, smooth, simulated tumbled, true tumbled, vertical scratch, matt, etc. Typically, Red-bodied/Sand-faced brick will have a red body with a colored sand.

Ad-mix or Thru-body

This unique process adds ingredients to the body of the brick to change the color of the unit. The additives are mixed into the clay material before the brick are formed. Therefore, “Thru-body” brick are the same color all throughout the unit. This style of production creates a very durable unit with more specific coloring, but sometimes costs more because of the additional processes and/or colorings.

Wood Moulded/Hand-made

Wood moulded/Hand-made is a brick process from yesteryear. These brick are formed in wood-moulds individual to each unit. Sand is applied to create different colors. The wood creates a soft texture appearance. The only difference between wood moulded and hand-made is with hand made a person throws the brick into molds instead of a machine. Both processes allow for beautiful color ranges and old characteristics like clay fold showing in the face of the brick. Modern manufacturing attempts to copy this look, but it is impossible to replicate without the moulds. Basically hand-made, so more costly than machine-made.

Thin Brick

This method of manufacturing has become popular in the last 10 years. Most thin brick are approximately 1” thick instead of the standard 3 5/8”. Many manufacturers cut the face off fired units in state-of –the art saw-houses. Some companies are able to cut both sides to get two faces from one brick. Other manufacturers are able to extrude the brick in a thin shape. Thin brick can be useful for indoor use, re-veneer jobs, parking decks with tilt-up concrete, or projects with weight issues, since they look like brick but have practically no weight. (strictly veneer)

So—-a brick is like most things—-not as simple as it appears. The methods of manufacture and materials involved make quite a difference in the finished product, and there are many styles, colors and sizes available. Here at Custom Brick and Supply Co. we truly have them all (going back to 1961) and can offer what you want. Please ask!